Innovative process developed to remove toxic 6PPD from end-of-life tires

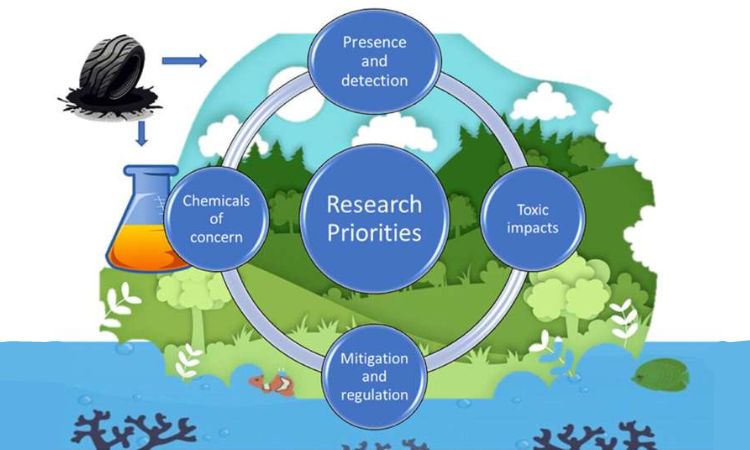

Researchers at the University of Delaware have introduced an innovative method to address the environmental and health challenges posed by toxic chemicals in end-of-life tires, particularly 6PPD. This molecule, used in tires for UV protection, releases harmful particles during tire wear and landfill decomposition, contaminating waterways and causing significant ecological harm, including fish die-offs.

The team, led by Dion Vlachos from the Center for Plastics Innovation, developed a chemical extraction process that removes 6PPD from crumb rubber. Using microwave reactors and solvents, they separate and convert 6PPD into safer chemicals. Unlike pyrolysis, which struggles to fully eliminate these harmful particles, this process allows for the remaining tire material to be repurposed effectively in asphalt, playground surfaces, and carbon black—a valuable industrial material.

This breakthrough has been validated at the lab scale and shows potential for cost-effective industrial application. However, researchers emphasize the need for pilot-scale testing to enable widespread adoption. With global tire waste projected to reach billions by 2030, innovative solutions like this are crucial for sustainable tire recycling.

For further details, visit the University of Delaware's article.

Weibold is an international consulting company specializing exclusively in end-of-life tire recycling and pyrolysis. Since 1999, we have helped companies grow and build profitable businesses.