Belgian innovator in OTR tire recycling technology looking for investors and strategic partners

Big Tyre Recycling Corporation (BTRC) – an innovator and ultra-high-pressure (UHP) water jetting technology supplier from Belgium – reports about its breakthroughs in technology for recycling extra-large mining and truck tires (up to R63) well known as off-the-road (OTR) tires. The company is currently looking for investors and strategic partners for construction and maintenance of OTR tire recycling units worldwide.

Currently, OTR tire recycling remains a pressing issue in both developed and developing countries all around the world. Every year hundreds of thousands tons of OTR tires are stockpiled around the world while recycling rates remain negligibly small. BTRC asserts it has found not just commercially viable, but a highly-profitable solution to tackle the global issue.

BTRC’s technology: ultra-high-pressure water jetting for OTR tire recycling

According to the innovator, out of all technologies available on the market today, the use of ultra-high-pressure water jetting is proven to be the most energy-efficient and the most economical solution for OTR tire recycling.

BTRC’s engineers explain that in the ultra-high-pressure water jetting the energy is applied exclusively toward pulverisation of rubber and is not dispersed by the need of cutting steel wires or bead wires in tire casings and sidewalls. The company claims that in the domain of OTR tire recycling its pulverizing approach has significant advantages over traditional cutting, shredding and grinding techniques destroying and cutting the steel.

The company asserts that the use of water in the process is an environment-friendly solution where more than 75% of the water are recycled. Fresh water consumption is reported to be less than 0,75 cubic meters per tire.

Recycled products from OTR tires using ultra-high-pressure water jetting

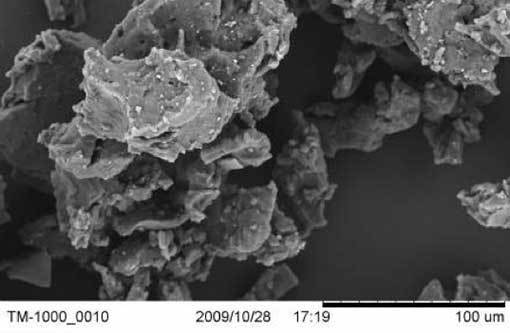

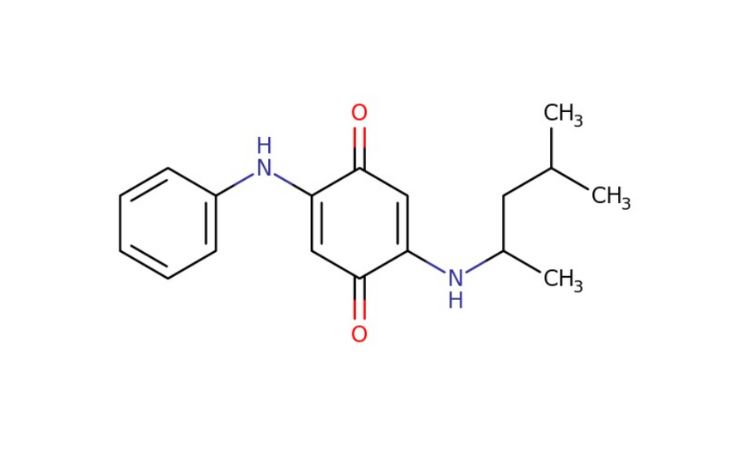

The recycled products from OTR tires, namely pulverized dry rubber powder (maximum 400 microns in size), clean synthetic fibre and clean steel fibres, can all have new life in industrial products, thus closing the loop of circular economy. All three products recovered by means of BTRC’s technology have significant advantages over materials recovered by means of regular shredding or grinding.

BTRC pinpoints that an extraordinary and interesting finding of recycling OTR tires using their innovative water jetting method is the recycled rubber powder itself, which is obtained in one single operation. The rubber powder, according to the company, has a proven vulcanising quality and is used as de-vulcanised product: namely, it is considered as a reclaim in powder format. It can be vulcanised, but it is mostly used as reclaim in new compounds, e.g. 55 PHR or more.

Over the last years, BTRC carried out extensive laboratory testing and researches using sample material from its former pilot plant in Belgium. Laboratory tests have proven high quality of the material and feasibility of the technology.

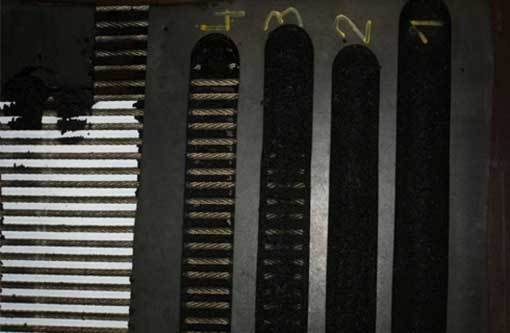

Belgian company also asserts that the same pulverizing water jetting technology can be used for recycling of end-of-life crawler tracks, large conveyor belts, as well as other solid rubber products. In both crawler tracks and large conveyor belts, BTRC’s UHP water jetting technology allows recovering expensive metal components (cleats and cables) and reuse them in the same products again (see photos below). This opens new business opportunities to rubber recyclers who use BTRC’s pulverizing technology.

In addition, BTRC reports that the technology ensures high purity of synthetic fibre recovered from OTR tires. According to the company, fibre from OTR tires is in high demand for reinforcing among conveyor belt manufacturers, solid tires and other industries. Thus, BTRC’s technology ensures broader profit sources to OTR tire processors and gives them access to huge unexploited markets.

The technology of UHP water jetting / pulverization and subsequent processing of the wet slurry has been developed by BTRC since 2008. The company has been working on advancing OTR tire recycling solutions backed by its own pilot plant and its team of researchers. Jacques Vervaet, the company’s founder, is convinced that the technology has a great future and will be the main solution to tackle the global problem of OTR tire recycling over the next decades.

BTRC is now looking for investors and strategic partners to commercialize the technology. Companies interested in BTRC’s technology are welcome to request technical data sheets (TDS) of the reclaim (powder) and send their inquiries to [email protected].

Article by Recycling Product News.

Weibold is an international consulting company specializing exclusively in end-of-life tire recycling and pyrolysis. Since 1999, we have helped companies grow and build profitable businesses.